- HUMAN Diagnostics Worldwide

- Lab Professionals

- Trends & Topics

Key levers to increase quality and safety in clinical chemistry

There are many factors that influence the quality of a test result. In addition to the pre-analytical steps, the reagents, the analysis system and the quality assurance measures play an important role. Depending on how much effort you want to put into achieving a high level of quality and safety, you can choose between different approaches. In clinical chemistry, a system approach can achieve maximum safety and quality with minimal effort. Learn more about the different approaches and the corresponding factors that influence the reliability of a patient result and why system reagents are the solution for worry-free daily laboratory work.

Test results: The interplay of reagents and instruments

The quality of a test result depends on the combined performance of reagent and instrument. One of the most important levers for obtaining high quality results is not only the quality of the reagents and the instrument, but also the quality of the reagent applications. Not every standard reagent application is suitable for every instrument. If there are no pre-installed applications, the laboratory has to establish and validate the application. Depending on the quality requirements of the laboratory, this can involve a great deal of effort. The parameters to be evaluated include, for example, precision, linearity and control recovery. If the laboratory uses equipment with pre-installed applications and the corresponding reagents from the same supplier, all these tests should already have been performed.

The role of reagent applications

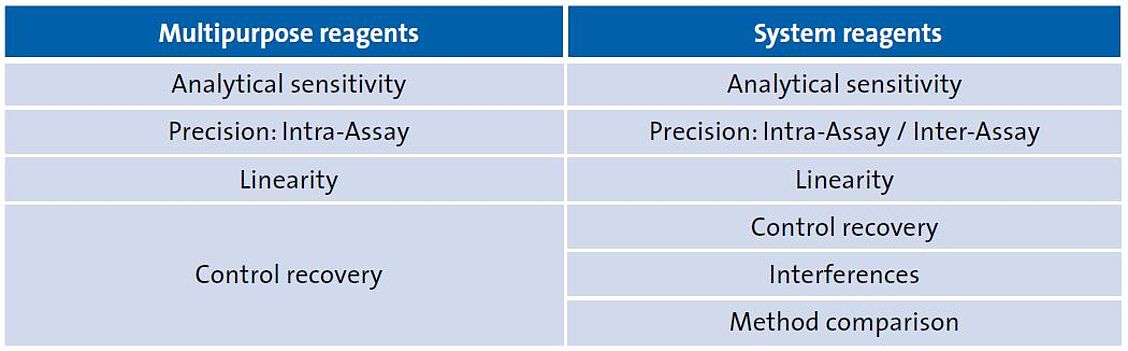

HUMAN offers thoroughly validated applications for all reagents in our clinical chemistry instrument portfolio like photometers, analyzers and systems. These applications, also called settings, are stored in the method database. The following specifications are evaluated and the results summarized in a validation report, which can be requested by the users. Multipurpose reagents offers everything you need, but if you want to achieve the highest level of quality, you typically rely on system reagents.

In order to ensure the functionality and quality of the validated applications, they should not bemodified by the user and should be updated regularly.

Process optimization: with system reagents to the highest degree of safety and quality

System reagents are ready-to-use and filled in barcoded bottles, the applications are created and evaluated for a specific analyzer. Some specifications depend on the filling volume of the reagent bottles and the device-specific reagent storage. They are determined for each kit variant and analyzer, such as the stability on board and the calibration stability. Besides this also real-time stability data are generated with three LOTS for three different shelf life times. LOT numbers and shelf life are identical for all system reagent bottle fillings from reagent production at a particular time. The LOT numbers are monitored in the analyzers and calibration is required when changing to a new reagent LOT. The shelf life is also monitored. Once the expiration date has passed, the system gives you a warning and the reagent can no longer be used.

Each barcode contains an individual number for each system reagent bottle. This unique bottle number is used to monitor the on board and calibration stability as well as the remaining test contents. At the end of the on-board stability guaranteed by HUMAN, the user must decide whether to continue using the reagent bottle for further measurements or whether to follow HUMAN‘s recommendation to change to another bottle. The system records all these data and connects the LOT data used with the respective patient result, a prerequisite for accreditation.

Economic efficiency and reduced reagent waste

For most parameters there are system reagent kits available for lower and higher test throughput. Depending on the sample volume in your laboratory, you can select the appropriate kit variant. This will not only reduce reagent waste and increase economic efficiency, but also labour, e.g. the number of calibrations within on board stability. For example system reagents for HumaStar 300SR and HumaStar 600 are identical and available for most parameters in 2 kit variants. The choice of the most appropriate kit variant automatically leads to considerable savings.

Summary of the 3 + of system reagents supporting a worry-free daily laboratory work:

Easy and secure reagent handling

- Filled in barcoded system bottles

- Pre-filled and barcoded reagent bottles prevent reagent mix-ups and contamination

- The system automatically matches the right application

Process optimization, economic efficiency and reduced reagent waste

- System captures the information on the remaining reagent by automated monitoring of reagent contents

- System reagent kits available for lower and higher test throughput for selecting the appropriate it variant and creating a quantity effect as well as a reduced reagent waste effect.

- Reduced labor by decreasing the number of calibrations within on board stability and therefore increased economic efficiency the right application

Quality checks by automatic reagent monitoring

- LOT numbers and shelf life are identical for all system reagent bottle fillings from reagent production at a particular time

- LOT numbers and shelf life are monitored in the analyzers

- Barcoded system reagent bottles with individual number for monitoring on board calibration and stability

- Highest quality to fulfill requirement for accreditation by connecting patient result with system

System reagents thus give you security, meet the highest quality requirements and can support you during accreditation. When will you start using the HUMAN system reagents?